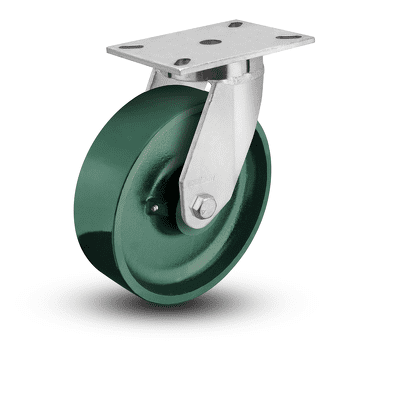

Yes, rigid casters are often the go-to choice for applications involving heavy loads. Here’s why they are preferred for such scenarios:

- High Load Capacity: Rigid casters are designed to handle and distribute heavy loads effectively. Because they do not have swiveling mechanisms, they are inherently more robust and can support greater weight compared to swivel casters.

- Stability: Rigid casters provide exceptional stability by maintaining a straight-line path. This stability is critical when dealing with heavy loads, as it helps prevent tipping, wobbling, and unintended changes in direction, ensuring the safety of both the load and the people handling it.

- Reduced Risk of Overturning: When moving heavy loads, the risk of overturning is a significant concern. Rigid casters minimize this risk by keeping the load moving in a predetermined direction and preventing sudden turns or shifts that can lead to instability.

- Even Load Distribution: Rigid casters can be used in combination with swivel casters on the same piece of equipment to provide a balance between maneuverability and load-bearing capacity. The rigid casters typically bear a significant portion of the load, reducing the strain on swivel casters and ensuring even weight distribution.

- Less Maintenance: Rigid casters have fewer moving parts than swivel casters, making them easier to maintain and less prone to wear and tear. This is important in heavy-load applications, where minimizing maintenance and downtime is essential.

Common examples of heavy-load applications that benefit from the use of rigid casters include:

- Industrial carts and dollies used to transport heavy materials and products within factories and warehouses.

- Material handling equipment like forklifts and pallet jacks that require stability when carrying large loads.

- Construction equipment such as concrete mixers, job site storage units, and utility trailers.

- Heavy machinery like metalworking equipment, CNC machines, and milling machines.

- Agricultural equipment, including wagons, plows, and combines.

- Conveyor systems handling heavy materials and products along assembly lines.

- Warehouse shelving units that need to support the weight of bulky inventory.

- Automotive and aerospace manufacturing equipment used to move large components and assemblies.

In all these applications, rigid casters play a vital role in ensuring that heavy loads can be moved safely and efficiently while maintaining stability and control.