Groove casters, also known as track or groove wheel casters, are specialized wheel components designed to operate within grooved tracks, channels, or rails. These casters are specifically engineered for applications where controlled and precise movement is essential, such as industrial and material handling equipment.

The primary feature of groove casters is their unique wheel design, which incorporates a groove, flange, or a V-groove in the wheel surface. This groove aligns with corresponding tracks or channels in the equipment or flooring, allowing the caster to follow a predetermined path. This design ensures stability and controlled movement, preventing lateral or swaying motion.

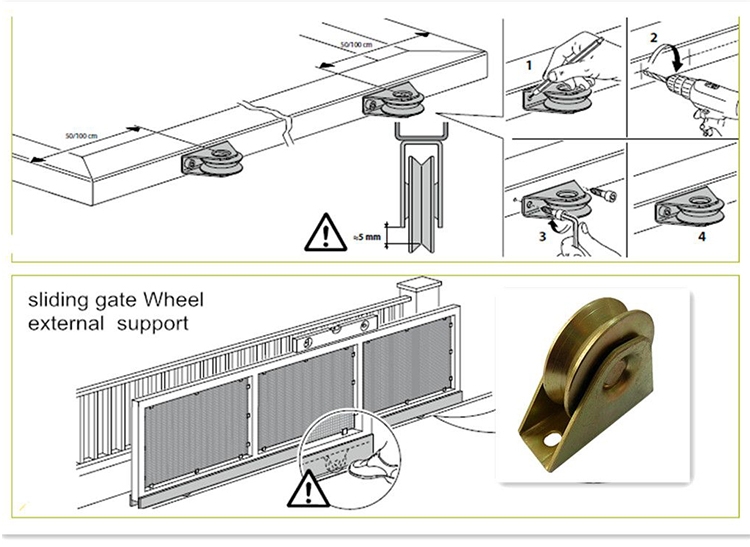

Groove casters are used in various applications, including conveyor systems, industrial carts, assembly lines, and sliding gates. They are invaluable in situations where objects or materials need to be transported or manipulated along a specific path, ensuring that they stay in alignment and maintain consistent movement.

These casters come in a range of sizes and materials to suit different load capacities and operational environments. Common materials include steel, nylon, or rubber, with steel being favored for heavy-duty applications.

Some groove casters feature swivel mechanisms, while others are fixed in place, depending on the application’s requirements. Additionally, these casters may be designed with flanges to provide additional guidance and stability within the grooved tracks.

In summary, groove casters are crucial components in scenarios where precision and controlled movement are imperative. Their unique wheel design and compatibility with grooved tracks make them indispensable in various industries, allowing for efficient, guided, and predictable motion of equipment and materials.