Spring-loaded casters, also known as shock-absorbing casters, are specialized wheel components designed to provide shock absorption and cushioning, making them ideal for applications where protecting delicate loads or reducing the impact of vibrations is crucial. These casters incorporate a spring mechanism into their design to mitigate the effects of shocks and vibrations on the equipment they support.

The primary feature of spring-loaded casters is their ability to dampen and absorb shocks and vibrations. This is achieved through the use of built-in springs that allow the caster to compress and rebound in response to impacts. The springs act as a buffer, reducing the stress and strain on both the caster and the transported load.

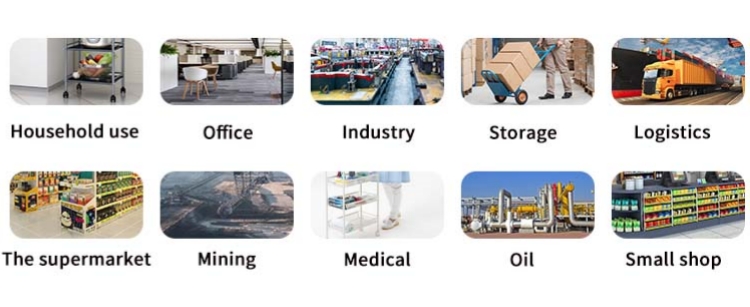

Spring-loaded casters are commonly used in industries such as aerospace, electronics, medical, and laboratory settings, where sensitive equipment or delicate materials need to be transported. They also find application in environments where vibrations can damage or disrupt operations, such as manufacturing facilities with heavy machinery.

These casters come in various sizes and load capacities to suit different needs. Materials like rubber or polyurethane are often chosen for their shock-absorbing properties and to minimize noise and floor protection.

Some spring-loaded casters feature swivel mechanisms, allowing for omnidirectional movement, while others remain fixed to maintain stability and control. Additionally, they are often equipped with brakes or locking mechanisms to ensure secure positioning when needed.

In summary, spring-loaded casters are crucial components for applications that demand shock absorption and load protection. Their ability to dampen impacts and vibrations ensures the safe and secure transport of sensitive materials and equipment while reducing wear and tear on caster systems and floors.