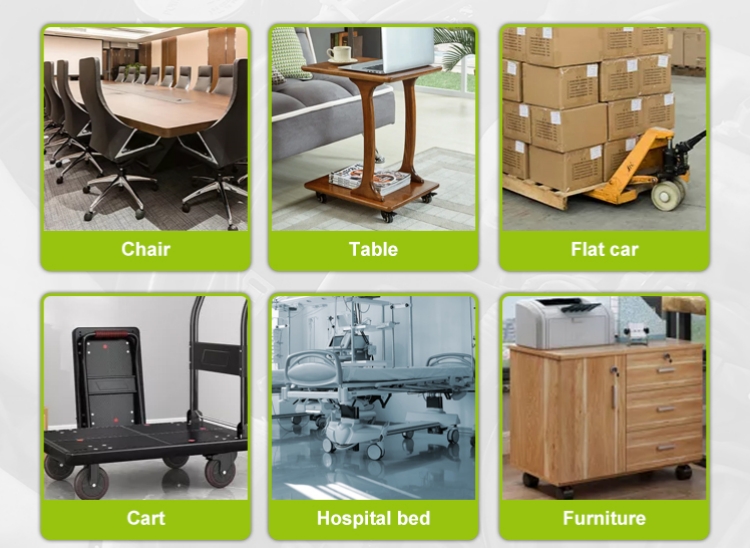

Rigid casters are essential components in a wide range of applications, from industrial machinery to furniture and material handling equipment. These casters are designed to provide stability and support by allowing movement in only one direction, typically forward and backward. They are distinct from swivel casters, which allow for omnidirectional movement.

The primary feature of rigid casters is their fixed wheel orientation. Unlike swivel casters, which can rotate 360 degrees, rigid casters have a fixed axle orientation, limiting movement to a single direction. This design choice ensures that they can bear heavy loads and provide exceptional stability, making them ideal for applications where precise, straight-line movement is required.

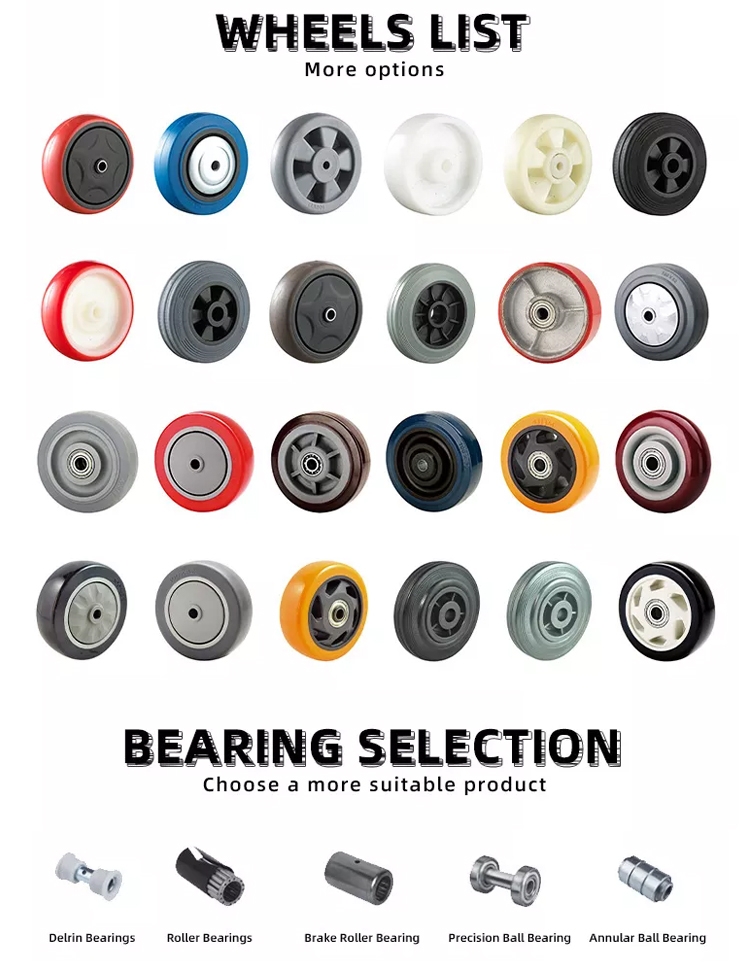

Rigid casters come in various sizes and materials to suit specific needs. Commonly used in industrial environments, they are often made from robust materials like steel or cast iron to withstand heavy-duty tasks. In contrast, in less demanding applications, you can find rigid casters with rubber or polyurethane wheels to minimize noise and protect delicate flooring surfaces.

In summary, rigid casters are essential components when you need to add stability and controlled movement to your equipment or furniture. Their straightforward design and dependable performance make them indispensable in numerous industries where precision and reliability are paramount.