Shock-absorbing casters, also known as cushioned or suspension casters, are specialized wheel components designed to reduce the impact of shocks, vibrations, and jolts during the transportation of sensitive loads. These casters are particularly valuable in industries where the protection of delicate materials or equipment is critical, such as aerospace, medical, and electronics manufacturing.

The key feature of shock-absorbing casters is their ability to cushion and absorb shocks and vibrations. This is typically achieved through the incorporation of a suspension mechanism, often consisting of springs, rubber elements, or pneumatic components, which dampen and minimize the effects of external forces. The caster’s design allows it to compress and rebound, providing a cushioning effect that protects both the load and the caster itself.

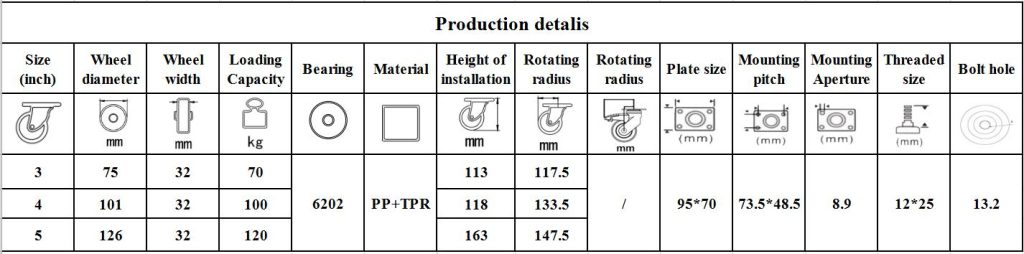

Shock-absorbing casters come in various sizes and load capacities to accommodate different needs. Materials like rubber or polyurethane are often chosen for their shock-absorbing properties and their capacity to reduce noise and protect sensitive flooring surfaces.

These casters are employed in a variety of applications, including laboratory equipment, precision manufacturing, and medical carts, where sensitive instruments or fragile materials must be transported without damage. They are also used in settings where vibrations can disrupt or damage operations, such as research facilities or cleanrooms.

Some shock-absorbing casters are equipped with swivel mechanisms, offering omnidirectional movement, while others remain fixed to maintain stability. Additionally, they may feature brakes or locking mechanisms to ensure secure positioning when needed.

In summary, shock-absorbing casters are essential components for applications that require the protection of delicate loads from shocks and vibrations. Their suspension mechanisms ensure the secure and damage-free transport of sensitive equipment and materials while minimizing wear and tear on caster systems and flooring.